Faster production of rotor blades for wind turbines thanks to laser projectors

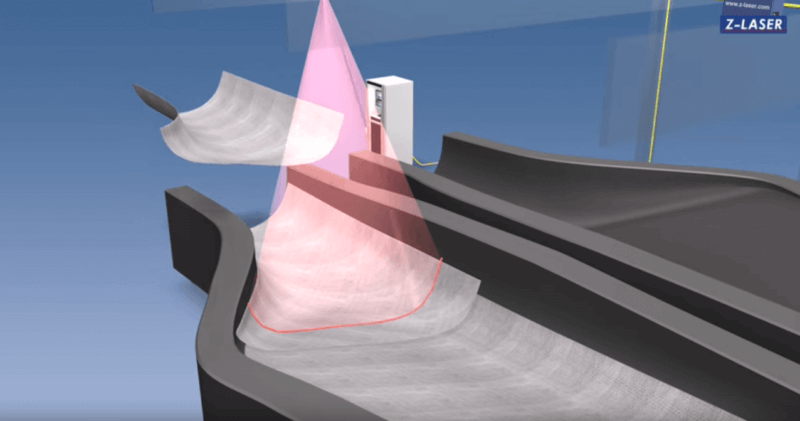

The manual laying process of fiberglass mats and prepregs in the manufacture of wind rotors can be significantly simplified and accelerated with the help of laser projectors. The laser projector shows the contours of each fiber mat in the form so that the layers can be positioned and aligned quickly, easily and precisely. The projector has interfaces for common 3D CAD formats.

Laser projectors increase productivity by up to 30%, improve quality (homogeneous structure of the wing), reduce errors and guide employees intuitively through the production process.

Special requirements:

Positioning of fiber mats, prepregs and carbon fiber decals: Our laser projectors have been specially optimized for complex positioning and alignment applications. They project the contours of every fiber mat or every decal that is to be placed in the mold, so that the production staff can position and align the layers quickly and precisely.

The projector has interfaces for all common 3D CAD design programs in order to display contours even on curved surfaces. It combines the advantages of the contour display with those of the computer control in order to simplify the production of complex composite components. As soon as the full laser projection is displayed, the laminator can immediately see where to place fiber mats, prepregs, the balsa core, struts or vacuum cups. This not only increases throughput, but also improves quality by reducing errors and manual rework.

In addition, individual letters, texts or numbers can be projected in order to define certain projection patterns in more detail. Depending on the manufacturing process, either the entire contour of the composite workpiece or the position of individual elements such as prepregs or decals can be displayed.

Your advantages:

- Exact positioning of GRP mats, prepregs and decals

- Higher productivity

- Improved quality

- Less mistakes and manual rework

- Intuitive guiding of the workers through the production process