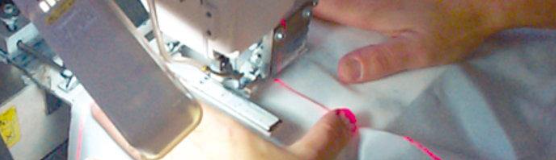

Laser use in Sewing Machines

laser technology in sewing machines

An integrated line laser module displays the seam pattern and ensures precise results at high working speeds.

Special Uses:

- Easy to integrate into sewing machines

- Compact design

- Good visibility of laser lines on all textile colours

- Built to withstand vibrations

- Cost-effectiveness

Advantages:

- Reduction of set-up time

- Increased speed and quality of work

- Fewer mistakes

- Cost reduction

While not common yet, lasers are starting to be incorporated into some modern sewing machines and can be added as an aftermarket accessory to existing machines. These lasers serve as visual guides, enhancing accuracy and efficiency in various sewing tasks. Here's how:

1. Guiding Straight Lines: Used for tasks like quilting or piecing, the laser projects a line onto the fabric, acting as a reference point for aligning fabric edges. This eliminates the need for drawing lines with chalk or pens, saving time and potential marking errors.

2. Precise Seam Allowances: The laser can be adjusted to project a line at a specific distance from the needle, corresponding to your desired seam allowance. This ensures consistent seam width throughout your project.

3. Aligning Corners and Markings: Some lasers even project crosshairs or additional lines. These can be used to precisely center designs or align markings on fabric, particularly helpful for intricate details or embroidery.

4. Additional Applications:

- Pleating fabrics: By using the laser as a guide, you can create evenly spaced pleats without using a specialized foot.

- Centering zippers: The laser can help ensure your zipper is perfectly centered on the seam line.

- Machine embroidery: Some lasers offer crosshairs to accurately position embroidery designs.

Overall, laser technology in sewing machines is still in its early stages but offers promising benefits for accuracy, efficiency, and convenience for sewers of all levels.