Product overview: Fluke Calibration P3200 Hydraulic Deadweight Tester

(Fluke Registration required before purchase. Please contact Laserman for more information on +61 8 9335 1718 )

(item no. 4185357, 4185369, 4185378, 4185384, 4185391, 4185406, 4185414, 4185423, 4185438, 4185445, 4185450, 4185461, 4185477)

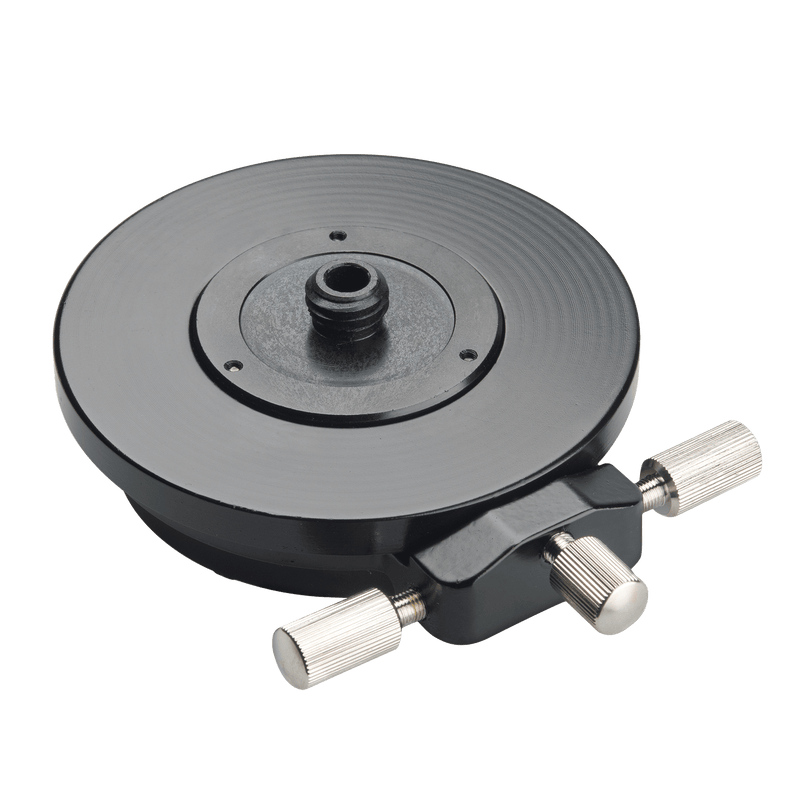

The P3200 models are available in single or dual piston formats for increased operating ranges. Units can be supplied in psi, bar, kgf/cm², and MPa. This robust instrument is highly accurate, quick and easy to use. Units feature a built-in priming pump for large volume applications, piston flotation indicators and a high quality screw press for fine pressure control.

Options

PressCal software for pressure calculations and certificate generation

Features

- Pressure ranges to 10,000 psi (700 bar)

- 0.015% of reading accuracy standard (0.008% optional)

- Single or dual piston formats

- Built-in hand pumps standard

- Mounted spirit level with adjustable feet

- Units can be trimmed to local gravity FOC

Models: Fluke Calibration P3200 Hydraulic Deadweight Tester

Pressure Range 20 to 700 bar

Pressure Range 1 to 35 bar

Pressure Range 10 to 500 psi

Pressure Range 1 to 35 kgf/cm²

Pressure Range 100 to 3,500 kPa

Pressure Range 0.1 to 3.5 MPa

Pressure Range 10 to 350 bar

Pressure Range 10 to 350 kgf/cm²

Pressure Range 100 to 5,000 psi

Pressure Range 1,000 to 35,000 kPa

Pressure Range 1 to 35 MPa

Pressure Range 20 to 700 kgf/cm²

Pressure Range 200 to 10,000 psi

Pressure Range 2,000 to 70,000 kPa

Pressure Range 2 to 70 MPa

Pressure Range 1 to 350 bar

Pressure Range 1 to 350 kgf/cm²

Pressure Range 10 to 5,000 psi

Pressure Range 100 to 35,000 kPa

Pressure Range 0.1 to 35 MPa

Pressure Range 1 to 700 bar

Pressure Range 1 to 700 kgf/cm²

Pressure Range 10 to 10,000 psi

Pressure Range 100 to 70,000 kPa

Pressure Range 0.1 to 70 MPa

Specifications: Fluke Calibration P3200 Hydraulic Deadweight Tester

| Pressure Ranges | |

| Distilled water operated | Ranges to 10,000 psi (700 bar) |

| Accuracy | |

| Accuracy1 | ±0.015% of reading (±0.008% optional) |

| 1. Accuracy based on % of reading from 10% to 100% of the piston range when used in accordance with the corrections found on the calibration certificate. Below 10% ± (accuracy class) x 10% of the piston range. | |

| Materials of Construction | |

| Standard weight material | Series 3 non-magnetic austenitic stainless steel |

| Weight density | 7.8 g/cm³ |

| Optional fractional weights | Solution heat treated aluminum |

| Weight density | 2.7 g/cm³ |

| Piston material | Tungsten carbide with nickel binder Density- 15.0 g/cm³ |

| Cylinder material | Hardened martensitic steel Tungsten carbide (water above 500 psi, 35 bar) |

| Thermal coefficients of expansion | Oil piston/cylinder 16.5 ppm/°C Water (above 500 psi, 35 bar) 11 ppm/°C |

| General | |

| Test port adaptors | 1/8, 1/4, 3/8 and 1/2 NPT or BSP |

| Instrument weight | 36 lbs (16 kg) |

| Instrument size (W x D x H) | 17.5 x 12 x 8.5 in (440 x 300 x 215 mm) |

| Mass set weight (typical) | 80 lbs (36 kg) |

| Reservoir volume | 150 cc |

| Screw press displacement | 5.5 cc |

| Pump displacement | 4.7 cc per stroke |

| O-ring seal materials | Buna N as standard, Viton and EPDM available |

| Weight Increments | |

| Minimum standard weight increments | Up to 500 psi (35 bar): 1 psi (0.1 bar) 500 to 5000 psi (35 to 350 bar): 10 psi (1 bar) 5000 to 20,000 psi (350 to 1400 bar): 20 psi (2 bar) Model P3112: 1 psi (0.1 bar) |

| Optional fractional weights | Up to 500 psi (35 bar): 0.1 psi (0.01 bar) 500 to 5000 psi (35 to 350 bar): 1 psi (0.1 bar) 5000 to 20,000 psi (350 to 1400 bar): 2 psi (0.2 bar) |

| Operating Fluids | |

| Operating fluids | Distilled or deionized water |

| Options | |

| PressCal software | Windows-based software program that allows users to easily apply all necessary corrections to enhance the deadweight tester performance. Calibration details are then stored and/or used to automatically create a calibration certificate. PressCal is provided as standard with all 0.008% instruments |

| Fluids | Instruments can be supplied for use with Skydrol or brake fluids. Due to the aggressive nature of these fluids the standard nitrile seals and the acrylic reservoir tube will be replaced by either Viton or EPDM seals (as applicable) and an aluminum reservoir tube. For these or any other specialty fluid applications, please consult the factory. |

Resources: Fluke Calibration P3200 Hydraulic Deadweight Tester

| Shipping | This Item Ships from Fremantle, Perth, Western Australia |

Please allow 2 - 10 days for your order to arrive.

Although Most Stocked Products will generally Ship Overnight. We source products from all over the world to bring you epic offers and the lowest prices. This means sometimes you have to wait a little longer to get your order but it's always worth it!

Returns are easy.

simply contact us for a returns number and send your item to our returns centre for fast processing. We'll get you a replacement or refund in a snap!

Description

Product overview: Fluke Calibration P3200 Hydraulic Deadweight Tester

(Fluke Registration required before purchase. Please contact Laserman for more information on +61 8 9335 1718 )

(item no. 4185357, 4185369, 4185378, 4185384, 4185391, 4185406, 4185414, 4185423, 4185438, 4185445, 4185450, 4185461, 4185477)

The P3200 models are available in single or dual piston formats for increased operating ranges. Units can be supplied in psi, bar, kgf/cm², and MPa. This robust instrument is highly accurate, quick and easy to use. Units feature a built-in priming pump for large volume applications, piston flotation indicators and a high quality screw press for fine pressure control.

Options

PressCal software for pressure calculations and certificate generation

Features

- Pressure ranges to 10,000 psi (700 bar)

- 0.015% of reading accuracy standard (0.008% optional)

- Single or dual piston formats

- Built-in hand pumps standard

- Mounted spirit level with adjustable feet

- Units can be trimmed to local gravity FOC

Models: Fluke Calibration P3200 Hydraulic Deadweight Tester

Pressure Range 20 to 700 bar

Pressure Range 1 to 35 bar

Pressure Range 10 to 500 psi

Pressure Range 1 to 35 kgf/cm²

Pressure Range 100 to 3,500 kPa

Pressure Range 0.1 to 3.5 MPa

Pressure Range 10 to 350 bar

Pressure Range 10 to 350 kgf/cm²

Pressure Range 100 to 5,000 psi

Pressure Range 1,000 to 35,000 kPa

Pressure Range 1 to 35 MPa

Pressure Range 20 to 700 kgf/cm²

Pressure Range 200 to 10,000 psi

Pressure Range 2,000 to 70,000 kPa

Pressure Range 2 to 70 MPa

Pressure Range 1 to 350 bar

Pressure Range 1 to 350 kgf/cm²

Pressure Range 10 to 5,000 psi

Pressure Range 100 to 35,000 kPa

Pressure Range 0.1 to 35 MPa

Pressure Range 1 to 700 bar

Pressure Range 1 to 700 kgf/cm²

Pressure Range 10 to 10,000 psi

Pressure Range 100 to 70,000 kPa

Pressure Range 0.1 to 70 MPa

Specifications: Fluke Calibration P3200 Hydraulic Deadweight Tester

| Pressure Ranges | |

| Distilled water operated | Ranges to 10,000 psi (700 bar) |

| Accuracy | |

| Accuracy1 | ±0.015% of reading (±0.008% optional) |

| 1. Accuracy based on % of reading from 10% to 100% of the piston range when used in accordance with the corrections found on the calibration certificate. Below 10% ± (accuracy class) x 10% of the piston range. | |

| Materials of Construction | |

| Standard weight material | Series 3 non-magnetic austenitic stainless steel |

| Weight density | 7.8 g/cm³ |

| Optional fractional weights | Solution heat treated aluminum |

| Weight density | 2.7 g/cm³ |

| Piston material | Tungsten carbide with nickel binder Density- 15.0 g/cm³ |

| Cylinder material | Hardened martensitic steel Tungsten carbide (water above 500 psi, 35 bar) |

| Thermal coefficients of expansion | Oil piston/cylinder 16.5 ppm/°C Water (above 500 psi, 35 bar) 11 ppm/°C |

| General | |

| Test port adaptors | 1/8, 1/4, 3/8 and 1/2 NPT or BSP |

| Instrument weight | 36 lbs (16 kg) |

| Instrument size (W x D x H) | 17.5 x 12 x 8.5 in (440 x 300 x 215 mm) |

| Mass set weight (typical) | 80 lbs (36 kg) |

| Reservoir volume | 150 cc |

| Screw press displacement | 5.5 cc |

| Pump displacement | 4.7 cc per stroke |

| O-ring seal materials | Buna N as standard, Viton and EPDM available |

| Weight Increments | |

| Minimum standard weight increments | Up to 500 psi (35 bar): 1 psi (0.1 bar) 500 to 5000 psi (35 to 350 bar): 10 psi (1 bar) 5000 to 20,000 psi (350 to 1400 bar): 20 psi (2 bar) Model P3112: 1 psi (0.1 bar) |

| Optional fractional weights | Up to 500 psi (35 bar): 0.1 psi (0.01 bar) 500 to 5000 psi (35 to 350 bar): 1 psi (0.1 bar) 5000 to 20,000 psi (350 to 1400 bar): 2 psi (0.2 bar) |

| Operating Fluids | |

| Operating fluids | Distilled or deionized water |

| Options | |

| PressCal software | Windows-based software program that allows users to easily apply all necessary corrections to enhance the deadweight tester performance. Calibration details are then stored and/or used to automatically create a calibration certificate. PressCal is provided as standard with all 0.008% instruments |

| Fluids | Instruments can be supplied for use with Skydrol or brake fluids. Due to the aggressive nature of these fluids the standard nitrile seals and the acrylic reservoir tube will be replaced by either Viton or EPDM seals (as applicable) and an aluminum reservoir tube. For these or any other specialty fluid applications, please consult the factory. |

Resources: Fluke Calibration P3200 Hydraulic Deadweight Tester

Shipping

| Shipping | This item ships to |

Delivery & Returns

Please allow 2 - 10 days for your order to arrive.

Although Most Stocked Products will generally Ship Overnight. We source products from all over the world to bring you epic offers and the lowest prices. This means sometimes you have to wait a little longer to get your order but it's always worth it!

Returns are easy.

simply contact us for a returns number and send your item to our returns centre for fast processing. We'll get you a replacement or refund in a snap!

6 Great reasons to buy from us:

-

30 Days Return

If your product is faulty or damaged under manufacture warranty, simply send it back to us and we'll cheerfully replace it or fix the problem for you. -

Returns are Easy

Simply contact us for a returns number and send your item to our returns centre for fast processing. We'll get you a replacement or refund in a snap! -

Best Price Guarantee

In the unlikely event that you find your item cheaper at another online store, just let us know and we'll beat the competitor's pricing hands-down. -

We guarantee your satisfaction

We insist that you love everything you buy from us. If you're unhappy for any reason whatsoever, just let us know and we'll bend over backwards to make things right again. -

100% Safe & Secure

Ordering from Laserman Technologies is 100% safe and secure so you can rest easy. Your personal details are never shared, sold or rented to anyone either. -

Best Laser Warranties in the Business

Laserman the Best Laser Level, Pipe Laser and Laser Measuring Warranties in the Business - Now thats unbeatable value !!.